This series of air-cooled rectifier has all of the “advantages” of our standard Advantage Air Series rectifiers but is provided with “enhanced” features to better protect the safety of operators.

This series of air-cooled rectifier has all of the “advantages” of our standard Advantage Air Series rectifiers but is provided with “enhanced” features to better protect the safety of operators.

In 2007, in response to a growing interest for the enhancement of rectifier safety, IRT joined a committee that included CP service companies, manufacturers, corrosion specialists and electrical specialists from end-user companies. From a rectifier design perspective, ideas were put forth to minimize the risk to operators of accidental contact with exposed electrical components. As a result of the committee’s effort, the Impressed Current Cathodic Protection Rectifier Design-for-Safety Guideline was developed and endorsed by the Canadian Association of Petroleum Producers (CAPP) in October of 2009. The guideline is intended to assist CP manufacturing, operating, engineering, consulting and service companies with the designing, fabricating, marketing and procuring of rectifiers for impressed current CP systems with embedded safety-by-design features. For more info please follow this link: (CAPP Guideline). This Advantage (Safety Enhanced) series of rectifier was developed specifically to meet these guidelines.

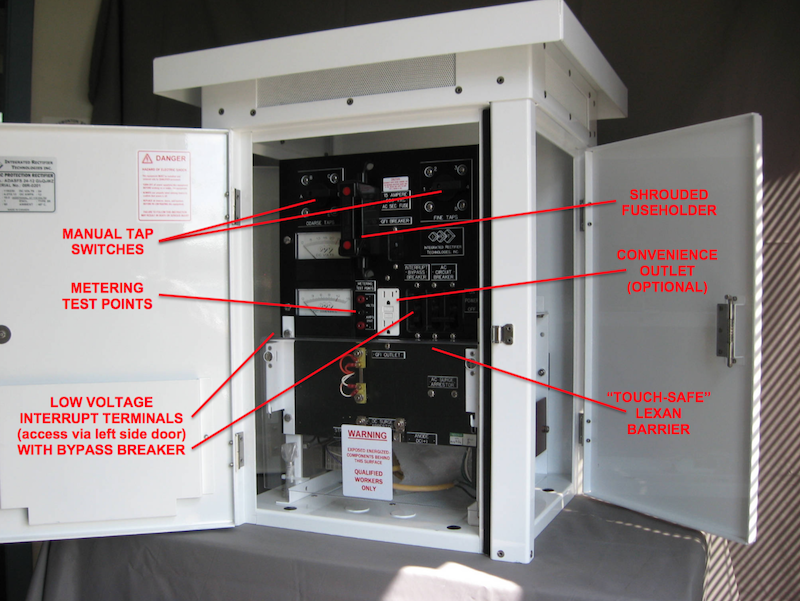

The general design and construction of the Advantage (Safety Enhanced) Air Series rectifiers is based on our standard Advantage Air Series but with the following revised and/or enhanced features.

- Standard transformer tap “link bar” type output adjustment is replaced with transformer tap “switch” adjustment. This not only enhances the safety for the operator but makes output adjustment easier and eliminates the possibility of an operator forgetting to suitably tighten a link bar connection. Note however, that this is not recommended for dusty environments.

- Standard open frame type fuse holders are replaced with fully shrouded types. This again not only provides enhanced safety but, due to the enclosed design of the shrouded fuse holders, the electrical connection to the fuse is superior for long term operation.

- All exposed electrical connections on the front of the rectifier instrument panel are shrouded by clear barriers. These barriers can be removed with tools if required for service purposes. The standard barrier for the DC output connections has an innovative one-piece molded design with captivated mounting hardware to eliminate the chance of the hardware being lost if the barrier is removed. Operators should be aware that contact with DC voltages can be as dangerous as AC voltages.

- This rectifier series is supplied with convenient test point terminals to allow for meter verification without having to remove the DC output connection barrier.

- Designated terminals are included inside the rectifier to allow an operator to safely connect an external interruption device for DC output interruption purposes without having to disconnect any of the rectifier electrical connections, as is often done. An access port is also included on the left side door to allow connection of cabling from the external interrupter but still allow the enclosure doors to be safely closed and secured.

- For those applications where AC powered devices may be used near the rectifier, a standard 110-120 volt ground fault interrupt (GFI) convenience outlet can be included inside the rectifier as well.

| Information Links: | |

|---|---|

| Product Data Sheet | Link |

| Product Specifications | Link |

| Product Operation Manual | Link |