The thermal conductivity of various metallic materials can vary greatly and this conductivity is affected by the type of the material and the coating (if any) applied to the material. If a transformer rectifier (TR) is to be installed in an area with a higher operating ambient (such as 35°C (95°F) or higher) and the TR enclosure is to be a CEMA, NEMA, CSA Type 4/4X/12 rated enclosure (non-vented type), the thermal conductivity of the finish applied must be considered.

In regards to the thermal conductivity factor for metal, the three most common metallic materials we use for our enclosures are carbon steel, aluminum and stainless steel.

- ALUMINUM: The thermal conductivity of pure aluminum is approximately 235 watts per kelvin per meter. Aluminum alloys can have much lower conductivities but are rarely as low as steel.

- CARBON STEEL: The thermal conductivity of carbon steel is much lower than aluminum at approximately 45 watts per kelvin per meter.

- STAINLESS STEEL: The thermal conductivity of stainless steel is much lower than carbon steel at approximately 15 watts per kelvin per meter.

In regards to material coating related to thermal conductivity, coating a material can either reduce or increase the thermal transfer properties. For transformer rectifier units mounted outdoors in sunlight, if the enclosure material is coated with a light color coating (our standard finish is white), this reduces the heat build-up in the enclosure as much of the solar radiation is reflected. However if the coating applied is a dark color, this can increase the heat build-up in the enclosure as much of the solar radiation is absorbed. An uncoated material such as stainless steel or aluminum will also tend absorb solar radiation more so than a material with a light colored coating; also an uncoated enclosure will not dissipate its internal heat as well as a coated enclosure. For proper rectifier cooling the external finish is more important than the material it is made from.

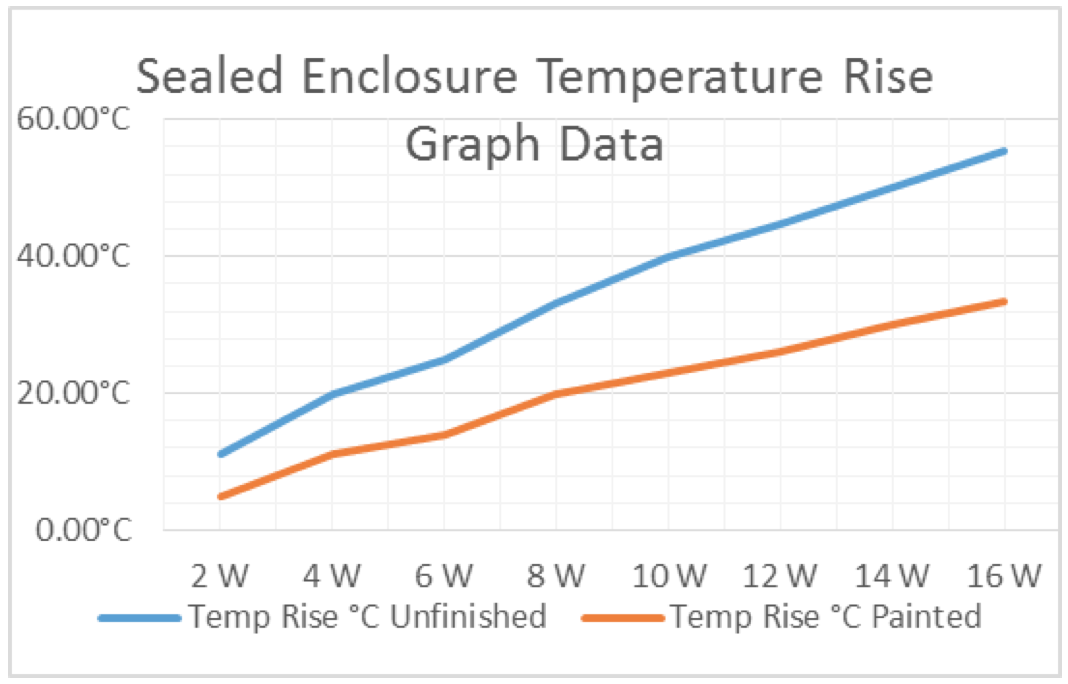

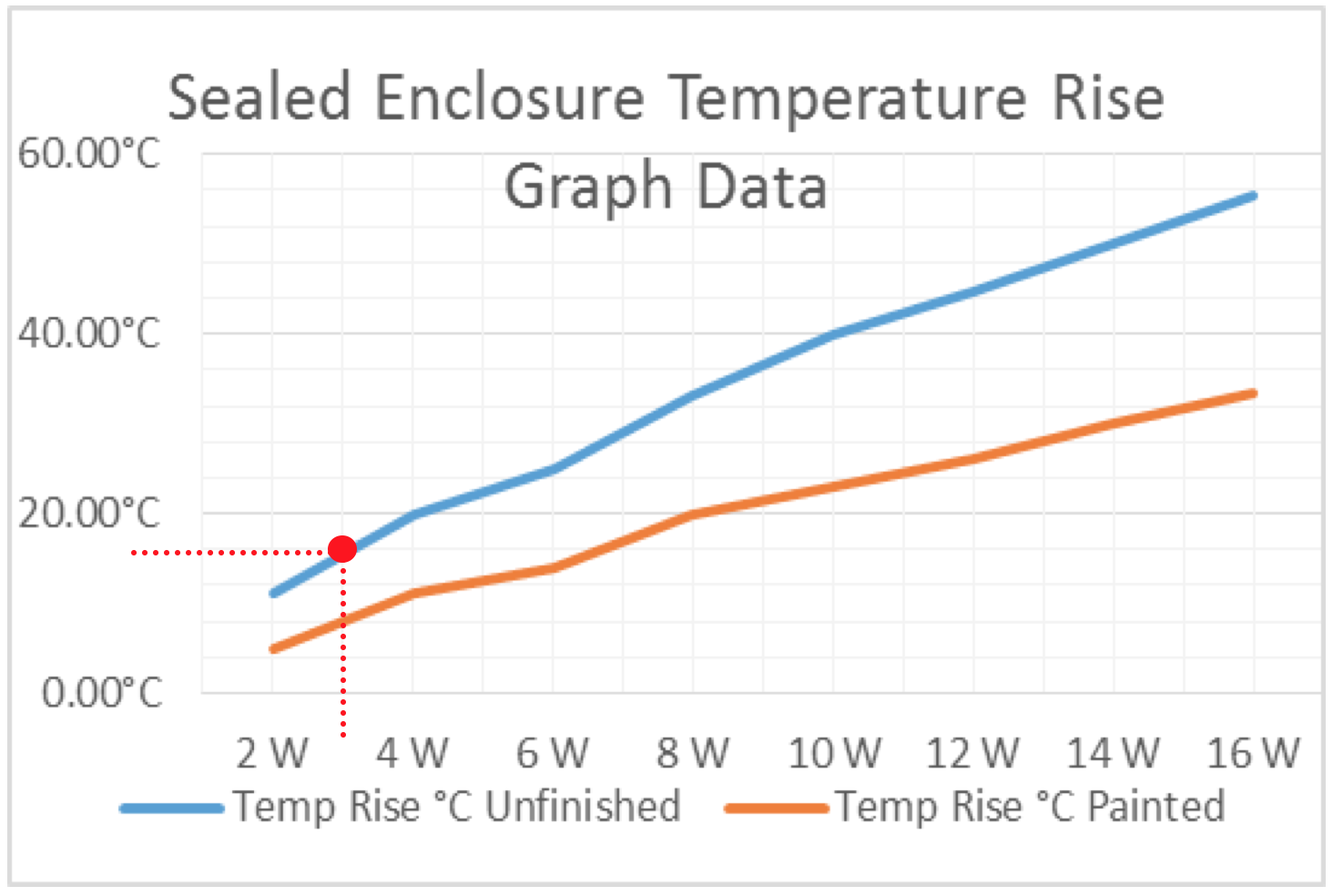

The graph below depicts the temperature rise for both a coated (painted) and non-coated (unfinished) metallic enclosure. The horizontal axis of the graph is in Watts per square foot (W/ft²) based on the losses of the equipment within the enclosure and the total surface area of the enclosure (solar loading is not included in the graph). The vertical axis on the left side of the graph is the temperature rise within the enclosure above the ambient temperature.

To utilize the graph, calculate the external surface area of the enclosure (3 sides are utilized for an enclosure that is wall mounted or if the rectifier utilizes a back-pan type of construction [such as the Benchmark series], and 4 sides are utilized for an enclosure that is pole mounted or utilizes floor stands). Calculate the total amount of losses within the enclosure including the main transformer, bridge, shunt(s), fuse(s), rheostat(s)/resistor(s) used for adjusting additional outputs, auxiliary transformers (used for powering optional equipment such as GPS interrupters) and anything else that generates heat. Take the calculated number of Watts and divide by the calculated surface area. Looking at the horizontal axis of the graph locate the calculated W/ft². From that point, go upwards until the intersection of either the painted (orange) or the unfinished (blue) line. At the intersection, go left towards the temperature (vertical axis on the left side of the graph) that point will indicate the average temperature rise within the enclosure. This is the average temperature (in the middle of the enclosure) and will increase towards the top of the enclosure (typically it is 18% hotter at the top of the enclosure versus the middle of the enclosure).

Example:

A rectifier has a total loss of 80.8 Watts within the enclosure. The enclosure size is 30”(H) x 30”(W) x 18”(D) utilizing 4 sides. And the maximum ambient temperature is 35°C.

Calculate the total surface area of the enclosure 27.50 ft².

Divide the total losses by the surface area: 80.8W / 27.50 ft² = 2.94 W/ft² (or 3 W/ft²)

The painted enclosure:

- Will have a rise of approximately 8.3°C for a total of 43.3°C inside the cabinet

- Will have a maximum (top) temperature of approximately 51.4°C

The unpainted enclosure:

- Will have a rise of approximately 15.9°C for a total of 50.9°C inside the cabinet

- Will have a maximum (top) temperature of approximately 60.4°C

For a transformer rectifier unit that will be installed in an area with a higher operating ambient (35°C (95°F) or higher), we suggest that the enclosure material & enclosure coating be considered. Based on the above thermal conductivity characteristics and weight, obviously the painted aluminum type enclosure is the best choice. However, the aluminum enclosures can be significantly more costly than a standard steel enclosure. As stainless steel not only has poor thermal conductivity characteristics but is also the most costly of the metallic materials we offer, this material would be a poor choice unless it is required for it’s very good corrosion resistant characteristics (such as in chemical plants, etc.). In summary, the best overall enclosure material choice for a transformer rectifier unit operating in a higher operating ambient (35°C (95°F) or higher) and requiring a CEMA, NEMA, CSA Type 4/4X/12 rated enclosure (non-vented type), would be a standard steel enclosure with a light color coating.

(Note: Due to the issues & expense of coating this material, IRT does not offer coated stainless steel enclosures.)

Enclosure Rating Definitions

For most “typical” Cathodic Protection type applications, a standard vented type enclosure (CEMA, NEMA, CSA Type 3R) can be, and is by far, the most used enclosure type. However, in certain applications such as dusty or corrosive atmospheres, wharves, offshore, chemical plants, mines, etc., the standard vented type enclosure may not be suitable. As such, we’re offering you the below information links on the various types of enclosures ratings available for your reference.

| Information Links: | |

|---|---|

| National Electrical Manufacturers Association (NEMA) Enclosure Rating Definitions | Link |

| Underwriters Laboratories Inc. (UL) Enclosure Rating Definitions | Link |

| Canadian Standards Association (CSA) Enclosure Rating Definitions | Link |

| Summary of Enclosure Rating Definitions | Link |